Cryatallization

Crystals are grown in many shapes, which are dependent upon

downstream processing or final product requirements. Crystal shapes can include

cubic, tetragonal, orthorhombic, hexagonal, monoclinic, triclinic, and trigonal.

In order for crystallization to take place a solution must be "supersaturated".

Supersaturation refers to a state in which the liquid (solvent) contains more

dissolved solids (solute) than can ordinarily be accomodated at that

temperature.

As with any separation method, equilibrium plays an

important role. Below is a general solubility curve for a solid that forms

hydrate (a compound that has one or more water molecules attached) as it cools.

In Figure 1, X may be any solid that can form hydrates such

as Na2S2O3. The number of hydrate molecules

shown in Figure 1 is strictly arbitrary and will vary for each substance.

So how do you grow crystals? Let's consider an example

that is fairly easy to envision. Take a pot of boiling water and add table salt

while stirring to make a water-salt solution. Continue adding salt until no

more salt will dissolve in the solution (this is a saturated solution). Now add

one final teaspoon of salt. The salt that will not dissolve will help the first

step in crystallization begin. This first step is called "nucleation" or

primary nucleation. The salt resting at the bottom of the pot will provide a

site for nucleation to occur.

Primary nucleation is the first step in

crystallization. Simply defined, it's the growth of a new crystalA

On an industrial scale, a large supersaturation driving

force is necessary to initiate primary nucleation. The initiation of primary

nucleation via this driving force is not fully understood which makes it

difficult to model (experiments are the best guide). Usually, the instantaneous

formation of many nuclei can be observed "crashing out" of the solution. You

can think of the supersaturation driving force as being created by a combination

of high solute concentration and rapid cooling. In the salt example, cooling

will be gradual so we need to provide a "seed" for the crystals to grow on. In

continuous crystallization, once primary nucleation has begun, the crystal size

distribution begins to take shape. Think about our salty water, as you look at

Figure 2 describing the progression of crystallization.

Figure 2: Progression of Crystallization

The second chief mechanism in crystallization is called

secondary nucleation. In this phase of crystallization, crystal growth is

initiated with contact. The contact can be between the solution and other

crystals, a mixer blade, a pipe, a vessel wall, etc. This phase of

crystallization occurs at lower supersaturation (than primary nucleation) where

crystal growth is optimal.

Secondary nucleation requires "seeds" or

existing crystals to perpetuate crystal growth. In our salt example, we

bypassed primary nucleation by "seeding" the solution with a final

teaspoon of salt. Secondary nucleation can be thought of as the

workhorse of crystallization.

Again, no complete theory is available to model secondary nucleation and

it's behavior can only be anticipated by experimentation. Mathematic

relationships do exist to correlate experimental data. However, correlating

experimental data to model crystallization is time consuming and often

considered extreme for batch operations, but can easily be justified for

continuous processes where larger capital expenditures are necessary. For batch

operations, only preliminary data measurements are truly necessary.

We've discussed how crystallization occurs once supersaturation is

reached, but how do we reach supersaturation? We have already covered one such

method in our salt crystallization example. Since the solubility of salt in

water decreases with decreasing temperature, as the solution cools, its

saturation increases until it reaches supersaturation and crystallization begins

(Figure 3). Cooling is one of the four most common methods of achieving

supersaturation. It should be noted that cooling will only help reach

supersaturation in systems where solubility and temperature are directly

related. Although this is nearly always the case, there are exceptions. In

Figure 3, you'll note that Ce2(SO4)3 actually

becomes less soluble in water at higher temperatures.

Figure 3: Solubilities of Several Solids

The four most common methods of reaching supersaturation in

industrial processes are:

1. Cooling (with some exceptions)

2. Solvent Evaporation

3. Drowning

4. Chemical Reaction

In an industrial setting, the

solute-solvent mixture is commonly referred to as the "mother

liquor". Drowning describes the addition of a nonsolvent to the

solution which decreases the solubility of the solid. A chemical reaction can

be used to alter the dissolved solid to decrease its solubility in the solvent,

thus working toward supersaturation. Each method of achieving supersaturation

has its own benefits. For cooling and evaporative crystallization,

supersaturation can be generated near a heat transfer surface and usually at

moderate rates. Drowning or reactive crystallization allows for localized,

rapid crystallization where the mixing mechanism can exert significant influence

on the product characteristics.

Equipment Used in Crystallization

1.Tank Crystallizers

This is probably the oldest and most basic method of

crystallization. In fact, the "pot of salt water" is a good example of tank

crystallization. Hot, saturated solutions are allowed to cool

in open tanks. After crystallization, the mother liquor is drained and the

crystals are collected. Controlling nucleation and the size of the crystals is

difficult. The crystallization is essentially just "allowed to happen". Heat

transfer coils and agitation can be used. Labor costs are high, thus this type

of crystallization is typically used only in the fine chemical or pharmaceutical

industries where the product value and preservation can justify the high

operating costs.

2.Scraped Surface Crystallizers

An example may be the Swenson-Walker crystallizer consisting of a

trough about 2 feet wide with a semi-circular bottom. The outside is jacketed

with cooling coils and an agitator blade gently passes close to the trough wall

removing crystals that grow on the vessel wall.

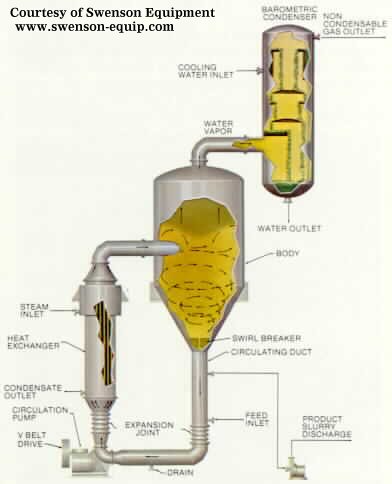

3.Forced Circulating Liquid Evaporator-Crystallizer

Just as the name implies, these crystallizers combine

crystallization and evaporation, thus the driving forces toward supersaturation.

The circulating liquid is forced through the tubeside of a steam heater. The

heated liquid flows into the vapor space of the crystallization vessel. Here,

flash evaporation occurs, reducing the amount of solvent in the solution

(increasing solute concentration), thus driving the mother liquor towards

supersaturation. The supersaturated liquor flows down through a tube, then up

through a fluidized area of crystals and liquor where crystallization takes

place via secondary nucleation. Larger product crystals are withdrawn while the

liquor is recycled, mixed with the feed, and reheated.

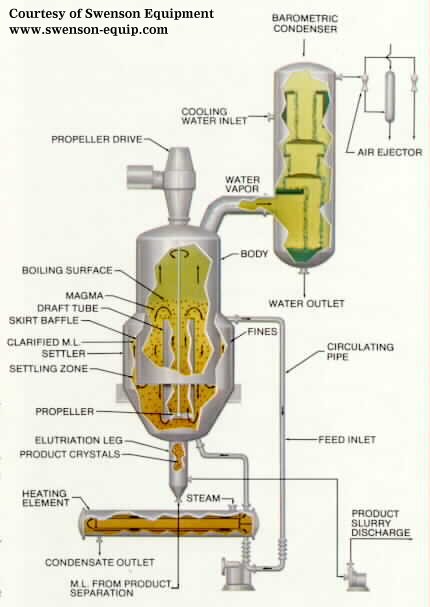

4.Circulating Magma Vacuum Crystallizer

In this type of crystallizer, the crystal/solution mixture (magma)

is circulated out of the vessel body. The magma is heated gently and mixed back

into the vessel. A vacuum in the vapor space causes boiling at the surface of

the liquid. The evaporation causes crystallization and the crystals are drawn

off near the bottom of the vessel body.

|