Depending on its processing and thermal history, it may exist both as an

amorphous (transparent) and as a semi-crystalline

(opaque and white) material. Its monomer can be synthesized by the

esterification reaction between

terephthalic acid and

ethylene glycol with water as a byproduct, or the

transesterification reaction between

ethylene glycol and

dimethyl terephthalate with

methanol as

a byproduct. Polymerization is through a polycondensation reaction of the

monomers (done immediately after esterification/transesterification) with

ethylene glycol as the byproduct (the ethylene glycol is recycled in

production).

The majority of the world's PET production is for synthetic fibers (in excess

of 60%) with bottle production accounting for around 30% of global demand. In

discussing textile applications, PET is generally referred to as simply "polyester"

while "PET" is used most often to refer to packaging applications.

Some of the trade names of PET products are Dacron, Diolen,

Terylene, andTrevira

fibers,

Cleartuf, Eastman PET and Polyclear bottle resins,

Hostaphan, elinex, and Mylar

films, and Arnite, Ertalyte, Impet,Rynite and

Valox

injection molding resins. The

polyester

Industry makes up about 18% of world polymer production and is third after

polyethylene (PE) and

polypropylene (PP).

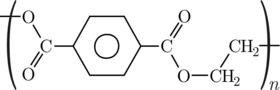

Chemical structure of polyethylene terephthalate

|

Contents

-

1 Uses

-

2 Intrinsic

viscosity

-

3 Drying

-

4 Copolymers

-

5 Crystals

-

6 Degradation

-

7 Antimony

-

8

Re-crystallization

-

9 Processing

equipment

-

10 See also

-

11 References

-

12 External

links

|

Uses

soft drink

bottle

PET can be semi-rigid to rigid, depending on its thickness, and is very

lightweight. It makes a good gas and fair moisture barrier, as well as a good

barrier to

alcohol (requires additional "Barrier" treatment) and

solvents. It

is strong and

impact-resistant. It is naturally colorless with high transparency.

When produced as a thin film (often known by the tradename

Mylar), PET is often

coated

with

aluminium to reduce its permeability, and to make it reflective and opaque.

PET bottles are excellent barrier materials and are widely used for

soft drinks, (see

carbonation). PET or Dacron is also used as a

thermal insulation layer on the outside of the

International Space Station as seen in an episode of

Modern Marvels "Sub Zero". For certain specialty

bottles, PET sandwiches an additional

polyvinyl alcohol to further reduce its

oxygen

permeability.

When filled with

glass

particles or

fibers, it becomes significantly

stiffer and more durable. This glass-filled plastic, in a semi-crystalline

formulation, is sold under the tradename Rynite, Arnite,

Hostadur, and Crastin.

Sails

are usually made of Dacron, a brand of PET fiber; colorful

lightweight

spinnakers are usually made of

nylon.

While most thermoplastics can, in principle, be recycled, PET bottle

recycling

is more practical than many other plastic applications. The primary reason is

that plastic carbonated soft drink bottles and

water

bottles are almost exclusively PET which makes them more easily identifiable

in a recycle stream. PET has a

resin identification code of 1. PET, as with many plastics, is also an

excellent candidate for thermal recycling (incineration) as it is composed of

carbon, hydrogen and oxygen with only trace amounts of catalyst elements (no

sulphur) and has the energy content of soft coal.

One of the uses for a recycled PET bottle is for the manufacture of

polar

fleece material. It can also make fiber for polyester products.

PET was patented in

1941 by the Calico Printers' Association of

Manchester.

The PET bottle was patented in

1973.

Intrinsic viscosity

One of the most important characteristics of PET is referred to as I.V. (intrinsic

viscosity).

The I.V. of the material, measured in

deciliters per gram (dl/g) is dependent upon the length of its polymer

chains. The longer the chains, the stiffer the material, and therefore the

higher the I.V. The average chain length of a particular batch of resin can be

controlled during

polymerization.

An I.V. of about:

- 0.60 dl/g: Would be appropriate for

fibre

- 0.65 dl/g: Film

- 0.76-0.84 dl/g: Bottles

- 0.85 dl/g: Tire

cord

Drying

PET is

hygroscopic, meaning that it naturally absorbs water from its surroundings.

However, when this 'damp' PET is then heated a chemical reaction known as

hydrolysis

takes place between the water and the PET which reduces its molecular weight

(IV) and its physical properties. This means that before the resin can be

processed in a molding machine, as much moisture as possible must be removed

from the resin. This is achieved through the use of a

desiccant

or dryers before the PET is fed into the processing equipment.

Inside the dryer, hot dry air is pumped into the bottom of the hopper

containing the resin so that it flows up through the pellets, removing moisture

on its way. The hot wet air leaves the top of the hopper and is first run

through an after-cooler, because it is easier to remove moisture from cold air

than hot air. The resulting cool wet air is then passed through a

desiccant

bed. Finally the cool dry air leaving the desiccant bed is re-heated in a

process heater and sent back through the same processes in a closed loop.

Typically residual moisture levels in the resin must be less than 40 parts per

million (parts of water per million parts of resin, by weight) before

processing. Dryer residence time should not be shorter than about four hours.

This is because drying the material in less than 4 hours would require a

temperature above 160 �C, at which level

hydrolysis

would begin inside the pellets before they could be dried out.

Copolymers

In addition to pure (homopolymer)

PET, PET modified by

copolymerization is also available.

In some cases, the modified properties of copolymer are more desirable for a

particular application. For example,

cyclohexane dimethanol (CHDM) can be added to the polymer backbone in place

of

ethylene glycol. Since this building block is much larger (6 additional

carbon atoms) than the ethylene glycol unit it replaces, it does not fit in with

the neighbouring chains the way an ethylene glycol unit would. This interferes

with crystallization and lowers the polymer's

melting temperature. Such PET is generally known as PETG (EastmanChemical

and SKchemicals are the only two manufacturers).

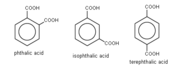

Replacing terephthalic acid (right) with isophthalic acid (center)

creates a kink in the PET chain, interfering with

crystallization and lowering the polymer's

melting point.

Another common modifier is isophthalic acid, replacing some of the 1,4-(para-)

linked

terephthalate units. The 1,2-(ortho-) or 1,3-(meta-)

linkage produces an angle in the chain, which also disturbs crystallinity.

Such copolymers are advantageous for certain moulding applications, such as

thermoforming, which is used for example to make tray or blister packagings

from PETG film, or

PETG sheet. On the other hand, crystallization is important in other

applications where mechanical and dimensional stability are important, such as

seat belts.

For PET bottles, the use of small amounts of CHDM or other comonomers can be

useful: if only small amounts of comonomers are used, crystallization is slowed

but not prevented entirely. As a result, bottles are obtainable via stretch

blow

molding ("SBM"), which are both clear and crystalline enough to be an

adequate barrier to aromas and even gases, such as carbon dioxide in carbonated

beverages.

Crystals

Crystallization occurs when polymer chains fold up on themselves in a

repeating, symmetrical pattern. Long polymer chains tend to become entangled on

themselves, which prevents full crystallization in all but the most carefully

controlled circumstances. PET is no exception to this rule; 60% crystallization

is the upper limit for commercial products, with the exception of polyester

fibers.

PET in its natural state is a crystalline resin. Clear products can be

produced by rapidly cooling molten polymer to form an

amorphous solid. Like

glass, amorphous

PET forms when its molecules are not given enough time to arrange themselves in

an orderly fashion as the melt is cooled. At room temperature the molecules are

frozen in place, but if enough heat energy is put back into them, they begin to

move again, allowing crystals to

nucleate

and grow. This procedure is known as

solid-state crystallization.

Like most materials, PET tends to produce many small

crystallites when crystallized from an amorphous solid, rather than forming

one large single crystal. Light tends to scatter as it crosses the boundaries

between crystallites and the amorphous regions between them. This scattering

means that crystalline PET is opaque and white in most cases.

Fiber

drawing is among the few industrial processes that produces a nearly

single-crystal product.

Degradation

PET is subject to various types of degradations during processing. The main

degradations that can occur are hydrolytic, thermal and probably most important

thermal oxidation. When PET degrades, several things happen: discoloration,

chain scissions resulting in reduced molecular weight, formation of

acetaldehyde and

cross-links

("gel" or "fish-eye" formation). Discoloration is due to the formation of

various chromophoric systems following prolonged thermal treatment at elevated

temperatures. This becomes a problem when the optical requirements of the

polymer are very high like for example in packaging applications. Acetaldehyde

is normally a colorless gas with a fruity smell. It forms naturally in fruit,

but it can cause an off-taste in bottled water. Acetaldehyde forms in PET

through the "abuse" of the material. High temperatures (PET decomposes above 300

�C or 570 �F), high pressures, extruder speeds (excessive shear flow raises

temperature) and long barrel residence times all contribute to the production of

acetaldehyde. When acetaldehyde is produced, some of it remains dissolved in the

walls of a container and then

diffuses

into the product stored inside, altering the taste and aroma. This is not such a

problem for non-consumables such as shampoo, for fruit juices, which already

contain acetaldehyde or for strong-tasting drinks, such as

soft drinks.

For bottled water, low acetaldehyde content is quite important, because if

nothing masks the aroma, even extremely low concentrations (10-20 parts per

billion parts of resin, by weight) of acetaldehyde can produce an off-taste. The

thermal and thermooxidative degradation results in poor processability

characteristics and performance of the material.

One way to alleviate this is to use a

copolymer.

Comonomers such as CHDM or

isophthalic acid lower the

melting temperature and reduces the degree of crystallinity of PET

(especially important when the material is used for bottle manufacturing). Thus

the resin can be plastically formed at lower temperatures and/or with lower

force. This helps to prevent degradation, reducing the acetaldehyde content of

the finished product to an acceptable (that is, unnoticeable) level. See

copolymers, above. Other ways to improve the stability of the polymer is by

using stabilizers, mainly antioxidants such as phosphites. Recently, molecular

level stabilization of the material using nanostructured chemicals has also been

considered.

Antimony

Antimony trioxide (Sb2O3) is a

catalyst that is often used in the production of PET. It remains in the

material and can thus in principle migrate out into food and drinks. Although

antimony trioxide is of low toxicity, its presence is still of concern. The

Swiss Federal Office of Public Health investigated the amount of antimony

migration, comparing waters bottled in PET and glass: the antimony

concentrations of the water in PET bottles was higher, but still well below the

allowed maximal

concentrations.[1]

(report available in German and French only) The Swiss Federal Office of Public

Health concluded that small amounts of antimony migrate from the PET into

bottled water, but that the health risk of the resulting low concentrations is

negligible (1% of the "tolerable daily intake" determined by the

WHO). A later (2006) but more widely publicized study by a group of

geochemists at the University of Heidelberg headed by William Shotyk found

similar amounts of antimony in water in PET bottles.[2]

The most recent WHO risk assessment for antimony in drinking water can be

found here:

[3]

Re-crystallization

PETE has

SPI

resin ID code 1

PET can be used to explore the

crystallization of

amorphous solids. The

resin identification code can be used to verify the type of plastic it is

made of: many plastic beverage bottles have the letters PET or PETE and a code

of 1 on the bottom, near the center. When a flame is held several inches below

the bottle and slowly brought closer, part of the material will visibly change.

This happens because high temperatures melt the PET. This releases the tension

that was frozen in during the blow molding process and the polymer chains will

shift to a more relaxed and disordered state, which results in shrinkage of the

softened area. Because of the decreased order of the polymer chains, there are

now fewer crystal nuclei. Consequently, when the

crystallites re-form upon cooling they grow larger than the original

crystallites in the bottle wall. Because the new crystallites are larger than

the wave length of light, they will now cause light to scatter, giving the

material an opaque white appearance.

Processing equipment

There are two basic molding methods, one-step and two-step. In two-step

molding, two separate machines are used. The first machine injection molds the

preform. The preform looks like a test tube. The bottle-cap threads are already

molded into place, and the body of the tube is significantly thicker, as it will

be inflated into its final shape in the second step using

stretch-blow molding.

In the second process, the preforms are heated rapidly and then inflated

against a two-part mold to form them into the final shape of the bottle.

Preforms (uninflated bottles) are now also used as containers for candy.

In

one-step machines, the entire process from raw material to finished

container is conducted within one machine, making it especially suitable for

molding non-standard shapes (custom molding), including

jars, flat oval,

flask shapes etc. Its greatest merit is the reduction in space, product handling

and energy, and far higher visual quality than can be achieved by the two-step

system.