Spinning Processes

Synthetic and Cellulosic

Fiber Formation Technology

Most

synthetic and cellulosic manufactured fibers are created by �extrusion� �

forcing a thick, viscous liquid (about the consistency of cold honey) through

the tiny holes of a device called a spinneret to form continuous filaments of

semi-solid polymer. Most

synthetic and cellulosic manufactured fibers are created by �extrusion� �

forcing a thick, viscous liquid (about the consistency of cold honey) through

the tiny holes of a device called a spinneret to form continuous filaments of

semi-solid polymer.

In their initial state, the fiber-forming polymers are solids and therefore

must be first converted into a fluid state for extrusion. This is usually

achieved by melting, if the polymers are thermoplastic synthetics (i.e., they

soften and melt when heated), or by dissolving them in a suitable solvent if

they are non-thermoplastic cellulosics. If they cannot be dissolved or melted

directly, they must be chemically treated to form soluble or thermoplastic

derivatives. Recent technologies have been developed for some specialty fibers

made of polymers that do not melt, dissolve, or form appropriate derivatives.

For these materials, the small fluid molecules are mixed and reacted to form the

otherwise intractable polymers during the extrusion process (if you are

interested in the latest information on extrusion,

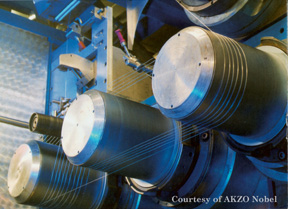

The Spinneret

The spinnerets used in the production of most manufactured fibers are

similar, in principle, to a bathroom shower head. A spinneret may have from one

to several hundred holes. The tiny openings are very sensitive to impurities and

corrosion. The liquid feeding them must be carefully filtered (not an easy task

with very viscous materials) and, in some cases, the spinneret must be made from

very expensive, corrosion-resistant metals. Maintenance is also critical, and

spinnerets must be removed and cleaned on a regular basis to prevent clogging.

As the filaments emerge from the holes in the spinneret, the liquid polymer

is converted first to a rubbery state and then solidified. This process of

extrusion and solidification of endless filaments is called spinning, not to be

confused with the textile operation of the same name, where short pieces of

staple fiber are twisted into yarn. There are four methods of spinning filaments

of manufactured fibers: wet, dry, melt, and gel spinning.

Wet Spinning

Wet spinning is the oldest process. It is used for fiber-forming

substances that have been dissolved in a solvent. The spinnerets are submerged

in a chemical bath and as the filaments emerge they precipitate from solution

and solidify.

Because the solution is extruded directly into the precipitating liquid, this

process for making fibers is called wet spinning.

Acrylic,

rayon,

aramid,

modacrylic and

spandex can be

produced by this process.

Dry Spinning

Dry spinning is also used for fiber-forming substances in solution.

However, instead of precipitating the polymer by dilution or chemical reaction,

solidification is achieved by evaporating the solvent in a stream of air or

inert gas.

The filaments do not come in contact with a precipitating liquid, eliminating

the need for drying and easing solvent recovery. This process may be used for

the production of

acetate,

triacetate, acrylic,

modacrylic,

PBI,

spandex, and

vinyon.

Melt Spinning

In

melt spinning, the fiber-forming substance is melted for extrusion through the

spinneret and then directly solidified by cooling.

Nylon,

olefin,

polyester,

saran and

sulfar are produced

in this manner.

Melt spun fibers can be extruded from the spinneret in different

cross-sectional shapes (round, trilobal, pentagonal, octagonal, and others).

Trilobal-shaped fibers reflect more light and give an attractive sparkle to

textiles.

Pentagonal-shaped and hollow fibers, when used in carpet, show less soil and

dirt. Octagonal-shaped fibers offer glitter-free effects. Hollow fibers trap

air, creating insulation and provide loft characteristics equal to, or better

than, down.

| Detailed production

flowcharts: |

| � Acrylic |

� Nylon

(Polyamide) |

� Polyester |

Gel Spinning

Gel spinning is a special process used to obtain high strength or

other special fiber properties. The polymer is not in a true liquid state

during extrusion. Not completely separated, as they would be in a true

solution, the polymer chains are bound together at various points in liquid

crystal form. This produces strong inter-chain forces in the resulting

filaments that can significantly increase the tensile strength of the

fibers. In addition, the liquid crystals are aligned along the fiber axis by

the shear forces during extrusion. The filaments emerge with an unusually

high degree of orientation relative to each other, further enhancing

strength. The process can also be described as dry-wet spinning, since the

filaments first pass through air and then are cooled further in a liquid

bath. Some high-strength polyethylene and aramid fibers are produced by gel

spinning.

Stretching and Orientation

While extruded fibers are solidifying, or in some cases even

after they have hardened, the filaments may be drawn to impart strength.

Drawing pulls the molecular chains together and orients them along the fiber

axis, creating a considerably stronger yarn.

|