| Jet Engine |

Types

There are a large number of different types of jet engines, all of which

achieve propulsion from a high speed exhaust jet.

| Type |

Description |

Advantages |

Disadvantages |

|

Water jet |

For propelling boats; squirts water out the back through a nozzle |

Can run in shallow water, high acceleration, no risk of engine

overload (unlike propellers), less noise and vibration, highly

manoeuvrable at all boat speeds, high speed efficiency, less vulnerable

to damage from debris, very reliable, more load flexibility, less

harmful to wildlife |

Can be less efficient than a propeller at low speed, more expensive,

higher weight in boat due to entrained water, will not perform well if

boat is heavier than the jet is sized for |

|

Motorjet |

Most primitive airbreathing jet engine. Essentially a

supercharged piston engine with a jet exhaust. |

Higher exhaust velocity than a propeller, offering better thrust at

high speed |

Heavy, inefficient and underpowered |

|

Turbojet |

Generic term for simple turbine engine |

Simplicity of design, efficient at supersonic speeds (~M2) |

A basic design, misses many improvements in efficiency and power for

subsonic flight, relatively noisy. |

| Low-bypass Turbofan |

One- or two-stage fan added in front bypasses a proportion of the

air through a bypass chamber surrounding the core. Compared with its

turbojet ancestor, this allows for more efficient operation with

somewhat less noise. This is the engine of high-speed military aircraft,

some smaller private jets, and older civilian airliners such as the

Boeing 707, the

McDonnell Douglas DC-8, and their derivatives. |

As with the turbojet, the design is aerodynamic, with only a modest

increase in diameter over the turbojet required to accommodate the

bypass fan and chamber. It is capable of supersonic speeds with minimal

thrust drop-off at high speeds and altitudes yet still more efficient

than the turbojet at subsonic operation. |

Noisier and less efficient than high-bypass turbofan, with less

static (Mach 0) thrust. Added complexity to accommodate dual shaft

designs. More inefficient than a turbojet around M2 due to higher

cross-sectional area. |

| High-bypass Turbofan |

First stage compressor drastically enlarged to provide bypass

airflow around engine core, and it provides significant amounts of

thrust. Compared to the low-bypass turbofan and no-bypass turbojet, the

high-bypass turbfan works on the principle of moving a great deal of air

somewhat faster, rather than a small amount extremely fast. This

translates into less noise. Most common form of jet engine in civilian

use today- used in airliners like the Boeing 747, most 737s, and all

Airbus aircraft. |

Quieter due to greater

mass flow and lower total exhaust speed, more efficient for a useful

range of subsonic airspeeds for same reason, cooler exhaust temperature.

High bypass variants exhibit good fuel economy. |

Greater complexity (additional ducting, usually multiple shafts) and

the need to contain heavy blades. Fan diameter can be extremely large,

especially in high bypass turbofans such as the

GE90. More subject to

FOD and ice damage. Top speed is limited due to the potential for

shockwaves to damage engine. Thrust lapse at higher speeds, which

necessitates huge diameters and introduces additional drag. |

| Rocket |

Carries all propellants and oxidants on-board, emits jet for

propulsion |

Very few moving parts, Mach 0 to Mach 25+, efficient at very high

speed (> Mach 10.0 or so), thrust/weight ratio over 100, no complex air

inlet, high compression ratio, very high speed (hypersonic)

exhaust, good cost/thrust ratio, fairly easy to test, works in a

vacuum-indeed works best exoatmospheric which is kinder on vehicle

structure at high speed, fairly small surface area to keep cool, and no

turbine in hot exhaust stream. |

Needs lots of propellant- very low

specific impulse � typically 100-450 seconds. Extreme thermal

stresses of combustion chamber can make reuse harder. Typically requires

carrying oxidiser on-board which increases risks. Extraordinarily noisy. |

| Ramjet |

Intake air is compressed entirely by speed of oncoming air and duct

shape (divergent) |

Very few moving parts, Mach 0.8 to Mach 5+, efficient at high speed

(> Mach 2.0 or so), lightest of all air-breathing jets (thrust/weight

ratio up to 30 at optimum speed), cooling much easier than turbojets as

no turbine blades to cool. |

Must have a high initial speed to function, inefficient at slow

speeds due to poor compression ratio, difficult to arrange shaft power

for accessories, usually limited to a small range of speeds, intake flow

must be slowed to subsonic speeds, noisy, fairly difficult to test,

finicky to keep lit. |

|

Turboprop (Turboshaft similar) |

Strictly not a jet at all � a gas turbine engine is used as

powerplant to drive propeller shaft (or rotor in the case of a

helicopter) |

High efficiency at lower subsonic airspeeds (300 knots plus), high

shaft power to weight |

Limited top speed (aeroplanes), somewhat noisy, complex transmission |

|

Propfan/ Unducted Fan |

Turboprop engine drives one or more propellers. Similar to a

turbofan without the fan cowling. |

Higher fuel efficiency, potentially less noisy than turbofans, could

lead to higher-speed commercial aircraft, popular in the 1980s during

fuel shortages |

Development of propfan engines has been very limited, typically more

noisy than turbofans, complexity |

|

Pulsejet |

Air is compressed and combusted intermittently instead of

continuously. Some designs use valves. |

Very simple design, commonly used on model aircraft |

Noisy, inefficient (low compression ratio), works poorly on a large

scale, valves on valved designs wear out quickly |

|

Pulse detonation engine |

Similar to a pulsejet, but combustion occurs as a

detonation instead of a

deflagration, may or may not need valves |

Maximum theoretical engine efficiency |

Extremely noisy, parts subject to extreme mechanical fatigue, hard

to start detonation, not practical for current use |

|

Air- augmented rocket |

Essentially a ramjet where intake air is compressed and burnt with

the exhaust from a rocket |

Mach 0 to Mach 4.5+ (can also run exoatmospheric), good efficiency

at Mach 2 to 4 |

Similar efficiency to rockets at low speed or exoatmospheric, inlet

difficulties, a relatively undeveloped and unexplored type, cooling

difficulties, very noisy, thrust/weight ratio is similar to ramjets. |

|

Scramjet |

Similar to a ramjet without a diffuser; airflow through the entire

engine remains supersonic |

Few mechanical parts, can operate at very high

Mach numbers (Mach 8 to 15) with good efficiencies |

Still in development stages, must have a very high initial speed to

function (Mach >6), cooling difficulties, very poor thrust/weight ratio

(~2), extreme aerodynamic complexity, airframe difficulties, testing

difficulties/expense |

|

Turborocket |

A turbojet where an additional

oxidizer such as

oxygen

is added to the airstream to increase maximum altitude |

Very close to existing designs, operates in very high altitude, wide

range of altitude and airspeed |

Airspeed limited to same range as turbojet engine, carrying oxidizer

like

LOX can be dangerous. Much heavier than simple rockets. |

|

Precooled jets/LACE |

Intake air is chilled to very low temperatures at inlet in a heat

exchanger before passing through a ramjet or turbojet engine. Can be

combined with a rocket engine for orbital insertion. |

Easily tested on ground. Very high thrust/weight ratios are possible

(~14) together with good fuel efficiency over a wide range of airspeeds,

mach 0-5.5+; this combination of efficiencies may permit launching to

orbit, single stage, or very rapid, very long distance intercontinental

travel. |

Exists only at the lab prototyping stage. Examples include

RB545,

SABRE,

ATREX. Requires liquid hydrogen fuel which has very low density and

heavily insulated tankage. |

All jet engines are reaction engines that generate thrust by emitting a

jet

of fluid rearwards at relatively high speed. The forces on the inside of the

engine needed to create this jet give a strong thrust on the engine which pushes

the craft forwards.

Jet engines make their jet from propellant from tankage that is attached to

the engine (as in a 'rocket') or from sucking in external fluid (very typically

air) and expelling it at higher speed; or more commonly, a combination of the

two sources.

Thrust

The motion impulse of the engine is equal to the fluid mass multiplied by the

speed at which the engine emits this mass:

- I = m c

where m is the fluid mass per second and c is the exhaust speed. In other

words, a vehicle gets the same thrust if it outputs a lot of exhaust very

slowly, or a little exhaust very quickly.

However, when an vehicle moves with certain velocity v, the fluid moves

towards it, creating an opposing ram drag at the intake:

- m v

Most types of jet engine have an intake, which provides the bulk of the fluid

exiting the exhaust. Conventional rocket motors, however, do not have an intake,

the oxidizer and fuel both being carried within the vehicle. Therefore, rocket

motors do not have ram drag; the gross thrust of the nozzle is the net thrust of

the engine. Consequently, the thrust characteristics of a rocket motor are

completely different from that of an air breathing jet engine.

The jet engine with an intake is only useful if the velocity of the gas from

the engine, c, is greater than the vehicle velocity, v, as the net engine thrust

is the same as if the gas were emitted with the velocity c-v. So the thrust is

actually equal to

- S = m (c-v)

Energy efficiency

For all jet engines the

propulsive efficiency (essentially

energy efficiency) is highest when the engine emits an exhaust jet at a

speed that is the same as, or nearly the same as, the vehicle velocity. The

exact formula for air-breathing engines as given in the literature,

Noise

Noise is due to shockwaves that form when the exhaust jet interacts with the

external air.

The intensity of the noise is proportional to the thrust as well as

proportional to the fourth power of the jet velocity.

Generally then, the lower speed exhaust jets emitted from engines such as

high bypass turbofans are the quietest, whereas the fastest jets are the

loudest.

Although some variation in jet speed can often be arranged from a jet engine

(such as by throttling back and adjusting the nozzle) it is difficult to vary

the jet speed from an engine over a very wide range. Therefore since engines for

supersonic vehicles such as Concorde, military jets and rockets inherently need

to have supersonic exhaust at top speed, so these vehicles are especially noisy

even at low speeds.

Common types

A turbojet engine is a type of

internal combustion engine often used to propel

aircraft.

Air is drawn into the rotating compressor via the intake and is compressed,

through successive stages, to a higher pressure before entering the combustion

chamber. Fuel is

mixed with the compressed air and ignited by flame in the eddy of a

flame

holder. This

combustion

process significantly raises the temperature and volume of the air. Hot

combustion products leaving the combustor expand through a gas

turbine,

where power is extracted to drive the compressor. This expansion process reduces

both the gas temperature and pressure but sufficient fuel is burnt so that both

parameters are usually still well above ambient conditions at exit from the

turbine. The gas stream is then expanded to ambient pressure via a propelling

nozzle, producing a high velocity jet as the exhaust. If the jet velocity

exceeds the aircraft flight velocity, there is a net forward

thrust upon the

airframe.

Under normal circumstances, the pumping action of the compressor prevents any

backflow, thus facilitating the continuous-flow process of the engine. Indeed,

the entire process is similar to a

four-stroke cycle, but with induction, compression, ignition, expansion and

exhaust taking place simultaneously, but in different sections of the engine.

The

efficiency of a jet engine is strongly dependent upon the

overall pressure ratio (combustor entry pressure/intake delivery pressure)

and the turbine inlet temperature of the cycle.

It is also perhaps instructive to compare turbojet engines with propeller

engines. Turbojet engines take a relatively small

mass of air and

accelerate it by a large amount, whereas a

propeller

takes a large mass of air and accelerates it by a small amount. The high-speed

exhaust of a turbojet engine makes it efficient at high speeds (especially

supersonic

speeds) and high altitudes. On slower aircraft and those required to fly short

stages, a

gas turbine-powered

propeller

engine, commonly known as a

turboprop,

is more common and much more efficient. Very small aircraft generally use

conventional

piston engines to drive a propeller but small turboprops are getting smaller

as engineering technology improves.

The turbojet described above is a single-spool design, in which a single

shaft connects the turbine to the compressor. Two spool designs have two

concentric turbine-compressor systems, that spin independently with the turbine

and compressors for each section connected from opposite ends of the engine via

concentric

shafts. This allows for a higher compression ratio as well as improved

compressor stability during engine throttle movements. Three spool designs also

exist.

Turbofan engines

Most modern jet engines are actually turbofans, where the low pressure

compressor acts as a fan, supplying supercharged air not only to the engine

core, but to a bypass duct. The bypass airflow either passes to a separate 'cold

nozzle' or mixes with low pressure turbine exhaust gases, before expanding

through a 'mixed flow nozzle'.

Turbofans are used for airliners because they give an exhaust speed that is

better matched to subsonic airliner's flight speed, conventional turbojet

engines generate an exhaust that ends up travelling very fast backwards, and

this wastes energy. By emitting the exhaust so that it ends up travelling more

slowly, better fuel consumption is achieved. In addition, the lower exhaust

speed gives much lower noise.

In the 1960s there was little difference between civil and military jet

engines, apart from the use of

afterburning in some (supersonic) applications. Civil turbofans today have a

low exhaust speed (low

specific thrust -net thrust divided by airflow) to keep jet noise to a

minimum and to improve fuel efficiency. Consequently the

bypass

ratio (bypass flow divided by core flow) is relatively high (ratios from 4:1

up to 8:1 are common). Only a single fan stage is required, because a low

specific thrust implies a low fan pressure ratio.

Today's military turbofans, however, have a relatively high specific thrust,

to maximize the thrust for a given frontal area, jet noise being of less concern

in military uses relative to civil uses. Multistage fans are normally needed to

reach the relatively high fan pressure ratio needed for high specific thrust.

Although high turbine inlet temperatures are often employed, the bypass ratio

tends to be low, usually significantly less than 2.0.

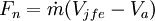

An approximate equation for calculating the net thrust of a jet engine, be it

a turbojet or a mixed turbofan, is:

where:

intake mass

flow rate

intake mass

flow rate

fully expanded jet velocity (in the exhaust plume)

fully expanded jet velocity (in the exhaust plume)

aircraft flight velocity

aircraft flight velocity

While the

term represents the gross thrust of the nozzle, the

term represents the gross thrust of the nozzle, the

term represents the ram drag of the intake.

term represents the ram drag of the intake.

|