Reliability engineering

Reliability engineering is an

engineering field, that deals with the study of

reliability: the ability of a

system or

component to perform its required functions under stated conditions for a

specified period of time.

It is often reported in terms of a

probability.

Overview

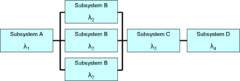

A Reliability Block Diagram

Reliability may be defined in several ways:

-

The idea that something is fit for purpose with respect to time;

-

The capacity of a device or system to perform as designed;

-

The resistance to failure of a device or system;

The ability of a device or system to perform a required function under

stated conditions for a specified period of

time; The probability that a

functional unit will perform its required function for a specified

interval under stated conditions. The ability of something to "fail

well" (fail without catastrophic consequences)

Reliability engineers rely heavily on

statistics,

probability theory, and

. Many engineering techniques are used in reliability

engineering, such as reliability prediction,

Weibull analysis, thermal management, reliability testing and accelerated

life testing. Because of the large number of reliability techniques, their

expense, and the varying degrees of reliability required for different

situations, most projects develop a

reliability program plan to specify the reliability tasks that will be

performed for that specific system.

The function of reliability engineering is to develop the reliability

requirements for the product, establish an adequate reliability program, and

perform appropriate analyses and tasks to ensure the product will meet its

requirements. These tasks are managed by a reliability engineer, who usually

holds an

accredited engineering degree and has additional reliability-specific

education and training. Reliability engineering is closely associated with

maintainability engineering and

logistics engineering. Many problems from other fields, such as

security engineering, can also be approached using reliability engineering

techniques. This article provides an overview of some of the most common

reliability engineering tasks. Please see the references for a more

comprehensive treatment.

Many types of

engineering employ reliability engineers and use the tools and methodology

of reliability engineering. For example:

System engineers design complex systems having a specified reliability Mechanical engineers may have to design a machine or system with a

specified reliability Automotive engineers have reliability requirements for the automobiles

(and components) which they design Electronics engineers must design and test their products for

reliability requirements. In software engineering and systems engineering the reliability engineering is the

subdiscipline of ensuring that a

system (or

a device in general) will perform its intended function(s) when operated in

a specified manner for a specified length of time. Reliability

engineering is performed throughout the entire

life cycle of a system, including development, test, production and

operation.

Reliability theory

Reliability theory is the foundation of reliability engineering. For

engineering purposes, reliability is defined as:

-

-

the

probability that a device will perform its intended function

during a specified period of time under stated conditions.

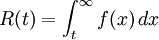

Mathematically, this may be expressed as,

-

-

, ,

-

- where

is the failure

probability density function and t

is the length of the period (which is assumed to start from time zero).

is the failure

probability density function and t

is the length of the period (which is assumed to start from time zero).

Reliability engineering is concerned with four key elements of this

definition:

-

First, reliability is a probability. This means that failure is

regarded as a

random phenomenon: it is a recurring event, and we do not express

any information on individual failures, the causes of failures, or

relationships between failures, except that the likelihood for failures

to occur varies over time according to the given probability function.

Reliability engineering is concerned with meeting the specified

probability of success, at a specified statistical

confidence level. Second, reliability is predicated on "intended function:" Generally,

this is taken to mean operation without

failure.

However, even if no individual part of the system fails, but the system

as a whole does not do what was intended, then it is still charged

against the system reliability. The system requirements specification is

the criterion against which reliability is measured. Third, reliability applies to a specified period of time. In

practical terms, this means that a system has a specified chance that it

will operate without failure before time

.

Reliability engineering ensures that components and materials will meet

the requirements during the specified time. Units other than time may

sometimes be used. The automotive industry might specify reliability in

terms of miles, the military might specify reliability of a gun for a

certain number of rounds fired. A piece of mechanical equipment may have

a reliability rating value in terms of cycles of use. .

Reliability engineering ensures that components and materials will meet

the requirements during the specified time. Units other than time may

sometimes be used. The automotive industry might specify reliability in

terms of miles, the military might specify reliability of a gun for a

certain number of rounds fired. A piece of mechanical equipment may have

a reliability rating value in terms of cycles of use. Fourth, reliability is restricted to operation under stated

conditions. This constraint is necessary because it is impossible to

design a system for unlimited conditions. A

Mars Rover will have different specified conditions than the family

car. The operating environment must be addressed during design and

testing.

|